Video: Export standard package for international artworks and sculptures

How to pack a sculpture for oversea shipping?

How we pack a sculpture for international shipping?

Compared to other general items, sculpture artwork has its own special characteristics, such as irregular shape, easy scratched surface, fragile... so when packaging sculpture, it has to be considered to its unique shape of each sculpture, its packaging program evaluation and design, to ensure the safety of sculpture in transit, to make sure that the sculpture can reach the hands of customers intact.

2.5meters high TEAR sculpture from Sculptor Mr. Richard Hudson in London UK

When packing sculptures, we need to pay extra attention to the following three points.

1. The way the sculpture is placed. In order to reduce the shaking of the sculpture in transit, it is necessary to choose the ideal placement angle according to the shape of the sculpture, so that the sculpture can be firmly fixed in the packing box.

Packing design and evaluation before packing process.

2. Reducing shaking. Long-distance shipping by sea or land may cause various degrees of shaking. This needs to be taken into account when packing. For example, the sculpture needs to be securely fastened in the box and filled with shock absorbing cotton between the box and the sculpture.

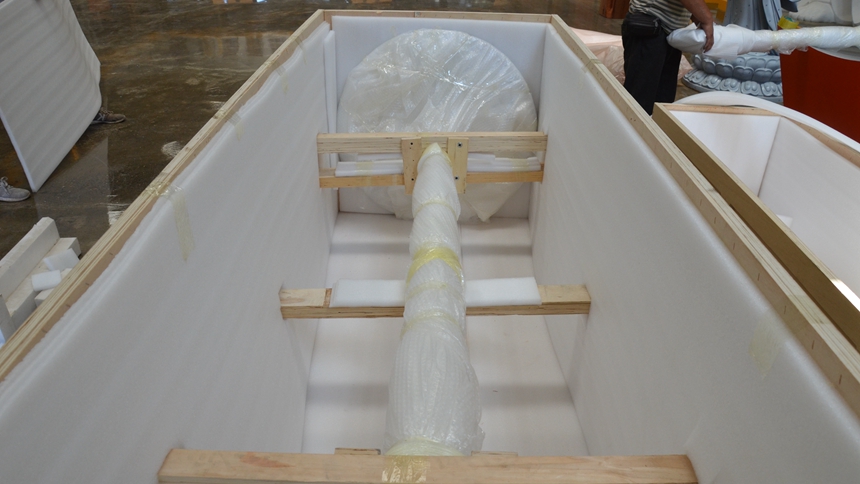

Internal secure and fix the sculpture during packing

3. Loading and unloading of the packing box; for large sculptures, they are generally very heavy, so the loading and unloading of the box requires the use of a forklift or crane. Therefore, the bottom of the box needs to have a pallet for forklift arm to enter, or lifting points for the crane; reasonable weight distribution and clear lifting points are very helpful for the sculpture loading and unloading operations.

Loading a plywood box into Container by Forklift

In current international shipping, it is common to use plywood boxes to pack sculptures. Plywood is a kind of raw material which is relatively easy to obtain , very strong and good fumigation-free packaging material; usually, the bottom of the plywood box has about 10cm high pallet, so that the forklift will be easy to load the box into the container or truck; Inside of plywood boxes are glued with 3cm thick collision-resistant soft material - pearl cotton, can play a cushioning effect, but also to reduce the sculpture and box contact and collision.

The most common packaging materials we use are:

a, bubble film;

b, pearl cotton;

c, shock absorbing foam;

d, tape;

e, strapping;

f, plywood boxes;

g, steel frame boxes, etc.

Packaging processes and steps.

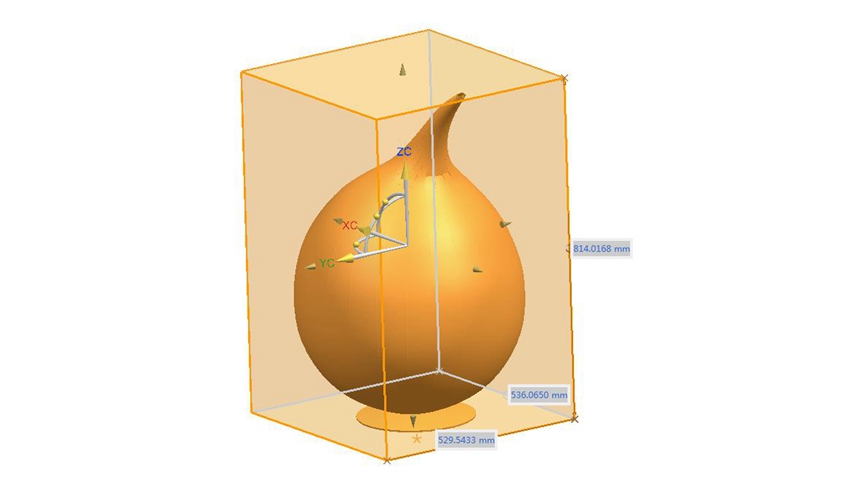

1. Evaluation and design of packaging solution.

In the pre-production stage of the sculpture, we will evaluate and design the packaging and transportation plan matching with the sculpture according to the final shape design and structure, size and weight of the sculpture, and will confirm the packaging material, packaging size, transportation method, loading and unloading plan of the sculpture.

2. Customization of plywood box or steel frame box.

Based on the confirmed packing scheme, to order packing boxes with our cooperated professional packing manufacturers. The packaging manufacturer will process and make the boxes according to the sculpture data we provide. The plywood used is brand new grade and the shock absorbing foam attached inside is also brand new. The steel frame packing boxes are generally made directly by our company, which can ensure the accuracy and quality of the steel frame boxes while saving costs.

3. Packaging.

According to the size of the sculpture, we have different packaging methods, for example,

-for small sculptures,

1. the innermost layer we choose soft and light pearl cotton to wrap the sculpture, wrapping 2-3 layers. Pearl cotton will not leave traces on the surface of the sculpture, and because of its soft nature, it will not wear and scratch the surface of the sculpture. Then wrap the sculpture with 2-3 layers of bubble film, with the bubbles facing inward, to enhance the buffering effect and play a good anti-collision role. Then use our custom tape to fix the bubble film.

2. Place the wrapped sculpture gently into the plywood box and use shock absorbing cotton to fill the gaps. If the empty space is large, or the sculpture and wooden box contact surface is small, it needs to use additional plywood to do auxiliary support to fix the sculpture. The auxiliary support also needs to be wrapped with pearl cotton and bubble film, so as not to touch the sculpture.

Inside soft packing for small sculptures

3. We use screws to seal the plywood boxes, so as to facilitate the unpacking and secondary use of the wooden boxes. If use nails to seal the box, it will cause great difficulties to open the box, or easy to cause damage to the internal sculpture. Finally, we need to mark on the outside of the wooden box that ‘this side is up’, ‘fragile’, ‘afraid of rain’, and ‘this side is open’.

Screwing seal the plywood box for sculpture package

-for larger sculptures,

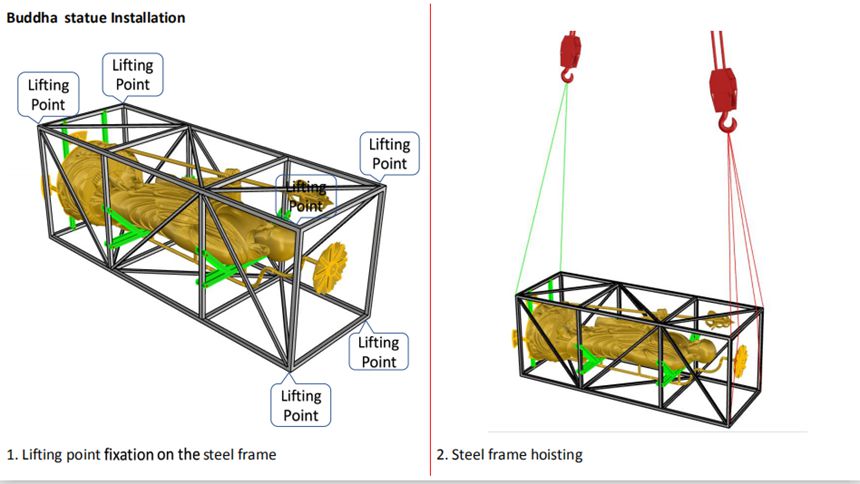

For some large sculptures, as their size usually exceeds the maximum size required for international transportation, they need to be transported in pieces and then assembled after they arrive at the site. For these types of sculptures, we generally use steel frame packaging. Steel frame packaging allows for the largest possible box size, which minimizes the number of sculptures in pieces and reduces the difficulty of on-site assembly and installation.

1. Each piece of sculpture will be packed with pearl cotton and bubble film, and then put into the steel frame box to fix. There are temporary fixing points welded to the steel frame and straps to secure each piece firmly in the steel frame box. The sculpture will be padded with rubber in advance where it contacts the steel frame.

2. There are lifting points on the steel frame box, so that the crane can easily load and unload the sculptures.

Steel frame package for large scale sculptures

3. For some customers who have very high requirements for packaging, we will also make a plywood box outside the steel frame box, forming a double-box packaging, which can better protection the sculpture.

Double packaged a sculpture with plywood box and steel frame